Welcome

Notio Limited is me, Roderick Mitchell.

I am an engineer and design specialist. I work with companies as an external or additional resource to generate concepts, evaluate technology or deliver complete, finished designs.

I am an experienced mechanical / mechatronic engineer and have spent 25 years working on the design, development and manufacture of machines and devices for a wide range of applications across many industries.

My experience has taught me the value of good design to a business. Investing in the design of your products and services delivers significant improvement in business performance.

I am a Fellow of the IMechE which demonstrates my wealth of experience, commitment and contribution to engineering.

Design

I am passionate about design.

Design has been shown to have the potential to deliver significant improvements in company profitability … reference the Design Council “Design Delivers for Business” publication, September 2012.

Most of my design experience is in the field on machine design, manufacturing processes and robotics, but I have also been involved in product design and designing for the retail environment.

Good communication and the right tools for the job are essential for an efficient design process. I start every design task with my pad and pencil – the easiest way to generate ideas – but quickly move to 3D CAD to develop concepts further so they can be visualised and reviewed.

More and more I am using photo realistic renders and rendered animations as tools to communiacte design with others.

I can provide the creative lead at the start of a project, apply rigour to the design process and am also happy to wrap up the final manufacturing details. The detail design is as critical as the concept generation as any final design is only as good as its weakest link!

SolidWorks provides the ability to design in a 3D environment, leading to improved visualisation and better design.

It can be used to …

- build quick models to explore concepts visually

- create mechanisms to analyse function

- animate assemblies to demonstrate a principle

- document everything for manufacture or user instructions

KeyShot provides the ability to create stunning visuals at every stage of a project.

It helps to …

- provide realism to a concept

- support early stage marketing activities

- generate engaging documentation for end users.

Engineering

Engineering is essential and underpins all design activities. It is a combination of knowledge, experience and judgement and without good engineering machines and products risk failure.

I can support the design process with the following engineering activities.

Analysis

Thorough and varied engineering analysis of concepts or designs can be used to help guide a project to a successful solution.

Analysis at different stages of a project can help to understand the relationships between elements of a design and how it relates to external elements.

Calculations

Basic calculations are essential to understanding performance and sizing components.

Motion analysis (speed and acceleration) and force (loads and free body diagrams) all contribute to accurate component selection.

FEA

FEA (Finite Element Analysis) is an invaluable tool built into modern CAD systems.

It is an easy and effective way to qualify the strength of components or assemblies, and hence reduce risk.

FMEA

FMEA (Failure Mode Effects Analysis) is a well known technique to identify failure modes and enable mitigating actions to be taken to reduce risk.

This technique can be applied at many stages of a project.

Case Studies

The best way to demonstrate experience is through case studies. The following examples show the breadth of projects I have undertaken.

Some are highly innovative and ground breaking, others are simply examples of well engineered solutions.

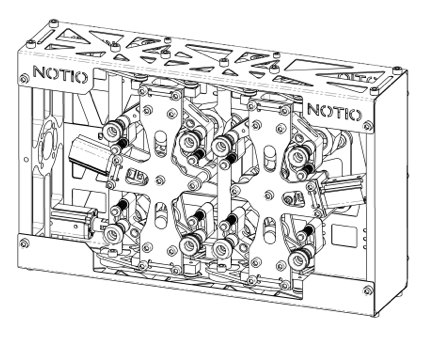

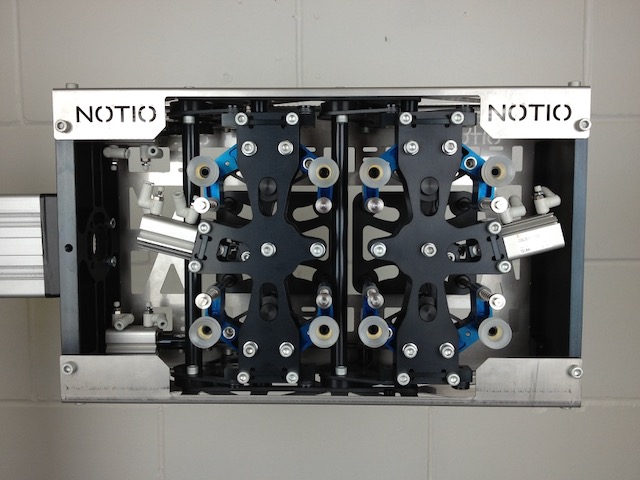

Light Weight, Multi-Functional Robot Gripper

Adding functionality to a 6 axis robot with limited load capacity by using an intricate, light weight gripper with multiple co-ordinated movements.

The need arose to retrofit an existing robotic demould cell to handle a new product. The challenge was to design a gripper that could pick 8 parts from the mould, re–orientate their position and angle, then place them in a set pattern in a tray. The gripper needed to weigh less than 4 Kgs.

A light weight gripper was designed that used a number of intricate mechanisms to perform the position and angular re– orientation in one operation, driven by one cylinder. To keep weight down many parts were manufactured from aerospace grade aluminium.

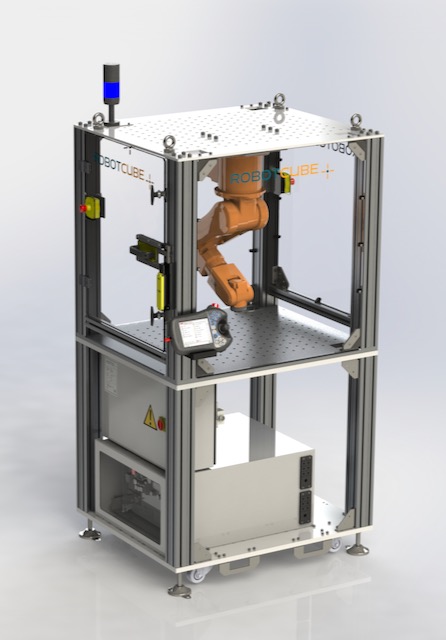

RobotCube … Compact Robot Cell

A robot cell with a very small footprint that was fully re-configurable.

A compact robot cell featuring an ABB IRB 120 robot mounted from the roof to transfer 8 moulded assemblies from one tray format to another, maintaining traceability. Parts were accurately placed within 10 seconds, giving a 30% productivity gain and significant labour reduction.

The cell occupied less than 1m2 as all services were built into the frame, and was designed to be re–configurable for future projects.

The concept was so successful that it has been developed further and branded as RobotCube.

Automated Retailing Machine

The worlds most advanced vending machine!

A large range of new concepts for automated retailing machine were developed from carousel based to tray moving systems.

A 3m tall carousel based machine was installed at the Goldsmith’s Boutique store at the Westfield Stratford City shopping centre to vend designer watches and jewellery 24 hours a day.

DVD Packaging Demoulding Robot and Buffering System

High speed demoulding in less than 0.5 seconds and 12 hours fully automated FIFO buffering.

DVD boxes are manufactured from a single polypropylene component with a living hinge. The robotic system demoulded the boxes, flexed and closed the living hinges, stacked / stored all closed boxes for up to 12 hours before automatically releasing them in sequence to the next process for film welding.

The solution included a high speed side entry demould robot capable of demoulding a 2+2 mould with a ‘mould held open’ or ‘mould delay’ time of less than 0.5 seconds. This was achieved through the use of high performance servo motors and high speed linear bearings.

Systems were designed and built for 2+2 and 4+4 configurations. The solution became the default industry solution and more than 100 systems were supplied globally.

2 Cavity High Speed Pail Demoulding Robot

An innovative approach to demoulding plastic pails using advanced servo motor mould tracking and high stiffness carbon fibre arms.

A leading plastic pail manufacturer needed a robot demould system for a new injection machine. A radical solution was designed that provided a step change in the speed with which plastic moulded pails could be demoulded, resulting in significant cycle time reduction.

The robot monitored and followed the position of the moving platen allowing the robot to enter the mould as it opened. The robot arm was manufactured from high strength carbon fibre tubes keeping them thin and strong. Pails were gripped by suction cups and were removed from the core before the mould was fully open due to accurate timing of the ejection sequence.

The system worked extremely well and solutions were developed for 1 cavity, 2 cavity and 2+2 cavity mould configurations resulting in big production output gains.

About

Get in touch …

If you have a design task that needs looking at why not contact me.

Complete the form below and I will get back in touch.